This week I worked on the neck, mainly. The weather is still pleasant, but the cold is coming and I don't have heat in the shop, so I'm trying to work as much as I can. Hopefully I can finish before it gets too terribly cold.

I put the dowel rod on the neck. I used a metal dowel screw to secure the rod onto the neck. The dowel rod will also be glued, so it will be pretty solid.

.

Next, I used a drill press to drill the holes for the tuning pegs.

.

To the left is a photo of the headstock after being drilled. It is now ready to accept the tuners

.

Next I checked the fit and alignment of the neck to the pot. The alignment is checked to make sure that it is correct before it is glued.

Next I attached the head to check that everything is correct.

.

Another photo of the neck attached.

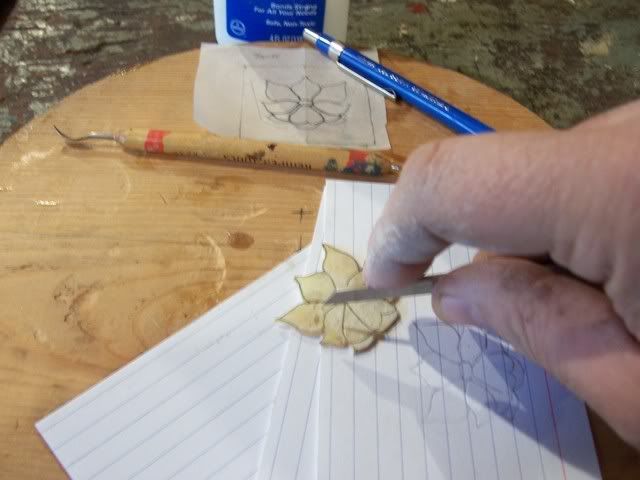

After I was sure that the neck fit properly, I prepared to cut the inlay. The photo on the left shows the jig that I built to cut the pearl.

.

.

The wooden platforms are what supports the pearl blank as I cut. The pearl is pretty fragile, so the support is needed or it will break. With any luck this piece of pearl will look like a lotus flower.

The wooden platforms are what supports the pearl blank as I cut. The pearl is pretty fragile, so the support is needed or it will break. With any luck this piece of pearl will look like a lotus flower..

A photo of the cut pearl.

A photo of the cut pearl.

A photo of the cut pearl.

A photo of the cut pearl..

.

After the pearl was cut and carved, it was time to inlay it into the neck. I used my trusty dremel with a router base to cut into the wood. When I inlay, I leave the pearl exposed above the wood slightly, then I sand the inlay flush with the wood. This removes most of the etched marks from the pearl, but there are enough remaining to use as a guide.

After the pearl was cut and carved, it was time to inlay it into the neck. I used my trusty dremel with a router base to cut into the wood. When I inlay, I leave the pearl exposed above the wood slightly, then I sand the inlay flush with the wood. This removes most of the etched marks from the pearl, but there are enough remaining to use as a guide..

And here the cavity has been routed and the neck is ready to be inlaid. I will glue the inlay onto the neck using a mixture of epoxy and dust from the fingerboard.

Well, that's all for this week. Next week I hope to finish the inlay and fret the neck. I have a lot of sanding, also.

.